Understanding pallet rack capacity and how to calculate it is of great importance for those working in the warehousing field. Warehouse pallet racking systems are necessary to keep your products off the ground and safe. For the safety of your warehouse, you must ensure that both the beams and racking frames are designed to hold the necessary weight to prevent a collapse.

What is pallet rack capacity?

Pallet rack systems are essential for any distribution center. They help store and organize products until they are ready to ship.

Pallet rack capacity refers to the distance between a beam level and the floor or the distance between two beam levels. You must also know the pallet rack frame capacity, that is, the total weight the upright frames can support. Doing so will help you determine if your pallet racking system can support the pallet load.

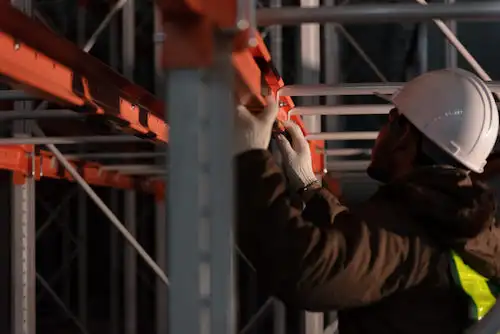

Pallet racks are steel structures consisting of upright frames made with posts and cross braces interconnected by horizontal beams. These beams support the pallet between each upright frame.

Typically, the average rack height is around 25 feet. However, with higher frames and increased space between the beams, it is possible to make more pallet space available.

Why is it important to know pallet rack capacity?

It is important to know your pallet rack capacity to keep your storage environment safe. You should also know the pallet rack weight capacity to ensure that you do not overload it. You need to know your pallet rack system capacity to maintain the overall strength and integrity of the structure.

Overloading your rack could lead to a potential accident, putting you or your workers in harm’s way.

Understanding pallet rack capacity helps you keep your products secure and accessible while maintaining the safety of your warehouse workers.

How does pallet rack frame capacity work?

Frame capacity is flexible and can be altered by the placement of the beams. Most modular pallet rack frames are adjustable, but only under the guidance of a trained professional. The larger the space between the beams, the lesser the weight the frame can support.

Since these rack frames are adjustable, it is possible to store heavier loads at the bottom and lighter ones at the top. Doing so reduces the risk of pallets toppling over enhancing overall security.

What factors determine pallet rack capacity?

Pallet rack capacity can vary between manufacturers due to the quality and gauge of the steel used.

However, when determining pallet rack system capacity, you should consider these factors:

Vertical beam spacing

Vertical beam spacing refers to the spacing which determines the capacity. Usually, the spacing is 48” but may be changed depending on the load. However, one must remember that the higher the vertical spacing, the lower the upright frame capacity.

Beam length

As you increase the length of the beams, the capacity to store products decreases. Since beam capacity is calculated in pairs, both beams should be identical for accurate pallet rack capacity. You should also consider the beam dimensions in your calculations.

Upright frame capacity

The upright frame capacity depends on various factors like beam weight, decking, and other accessories. The overall capacity does not change irrespective of the number of levels. However, as the height increases, the storage capacity of each level decreases.

Pallet weight and dimensions

Another crucial factor that determines pallet rack system capacity is the pallet load weight and its dimensions. The heaviest loads should be placed closest to the floor and the pallets should be evenly distributed on the racking to ensure stability.

How to calculate your required upright frame capacity?

If you need to know how to calculate pallet rack load capacity or upright frame capacity, you need to first consider the estimated maximum load weight for each beam level. Then you multiply it by the number of levels in the racking section. The result is the required pallet rack upright capacity.

What elements to consider when calculating a pallet rack capacity?

To calculate your pallet rack load capacity, you should know the beam and frame capacity, load on each beam level, and the vertical spacing.

Other elements that you need to consider when calculating include:

- Upright capacity: It involves determining how much space is needed between each beam level on the rack.

- Beam capacity: Beam capacity remains the same as stated by the manufacturer, but the frame capacity may change.

- Deflection of pallet rack beams: Rack beams that support the internal levels may have some deflection when heavier loads are put on them.

- Deck Capacity: Pallet racking decks ensure the even distribution of pallet loads through each level of storage.

It is important to know and understand how to determine pallet racking capacity to keep the warehouse and its workers safe.

Pallet rack safety considerations

Just like warehouse employees, pallet racks are crucial for warehouse operations.

Here are some safety considerations to ensure the safety of your warehouse:

Slab and soil conditions

Soil bearing capacity and flooring are the first elements of your pallet rack system. You must know how much weight your floor can withstand because the flooring will ultimately bear the weight of everything within the building. You should have a qualified engineer plan and prepare the right flooring for your warehouse, which you can find at SRSI.

Seismic requirements

Seismic requirements should be considered when engineering, manufacturing, or installing a pallet rack system. Typically, palet racks that have been manufactured to meet seismic safety requirements have a larger and thicker base plate used to anchor each column to the floor. A pallet rack designed for seismic application will be much heavier than one made for a low seismic application.

Pallet rack damage

Physical damage to pallet racks generally happens due to forklift truck collisions. You should keep the aisles clear and provide sufficient clearance space to avoid such damage.

Misaligned racks

Misaligned pallet racks can cause collapse or accidents. To prevent such incidents, follow the manufacturer’s instructions to install the pallet racks.

Determining the correct pallet rack frame capacity for your warehouse ensures a safe work environment. It also makes your warehouse compliant with occupational health and safety codes and optimizes your storage space for more efficient loading and picking. It is helpful to remember pallet rack can be mixed with other manual and/or automated material handling systems to optimize your operations. SRSI can provide everything from design to project management and systems services.

Skip to main content

Skip to main content