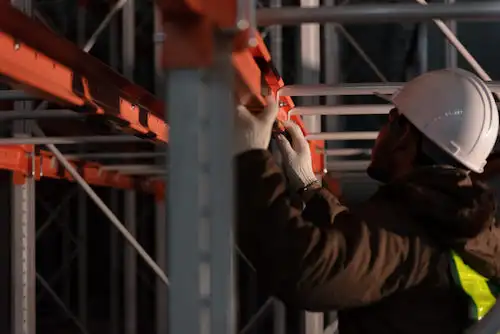

It’s not easy deciding what pallet racking system to use — one that for you, your needs, and your desires. It’s not just about knowing how to measure pallet racking systems. It’s far more complex. In an effort to help guide you during this important decision-making process, and give you quick tips on what to consider when purchasing a pallet racking system, we’ve compiled a list of challenges to consider to avoid costly mistakes.

How to order a new or used pallet racking system — tips to get it right.

It’s important to understand that warehouse pallet racking systems come in all shapes and sizes. Many customers that come to us at SRSI think ordering a custom pallet racking system is as simple as taking a picture of their warehouse and sending over some measurements. It’s much more complicated and nuanced than that. Why?

Because, each warehouse and its operations are different. It’s not just what materials or products you handle, but how you handle them. When ordering a pallet racking system design you’ll have to consider your budget, your staff, your logistical problems, your dimensions, and even state regulations.

Here’s a list of some common mistakes when it comes to picking a racking system for pallets – pitfalls you should avoid.

Cheap systems end up costing you a lot in the long run.

It’s a competitive world out there, and that competition is partly due to an overabundance of products. Today, you have multiple choices available whenever you want to buy a product. That includes pallet racking systems. One of the biggest characteristics is the price point. You can typically find just about every price tag on the market when it comes to racking systems for pallets. It’s important to value quality and performance over affordability. Cheap racks disappoint right out of the box and subsequently need replacements.

Little to no foresight.

It’s important to buy racks not just for your present needs but for what the future might demand of you. Invest in a pallet rack system that will adapt to your style, to your needs, and one that is universal in nature — otherwise, when you expand, you will need to replace the whole racking system.

Guessing weight and requirement.

There’s nothing worse when it comes to purchasing a racking system than “eyeballing it.” It’s important to understand what weight, measurements, and capacity you’ll need.

Taking a stab in the dark at what your warehouse pallet rack dimensions and its needs are undermines your safety and your warehouse’s capacity to work efficiently.

To forklift or not to forklift

Forklifts have become iconic when it comes to the way a warehouse operates. It’s important to take them into account. Will you need to access pallet racks with a forklift? Will you need to drive through them? What height will you need them to be? Folks constantly miscalculate their forklift’s requirements and buy the wrong pallet racking system. There are also many options to automate the actions forklifts perform. Is automation right for your warehouse operations?

Not including your employees in the decision

Your employees, your staff, your warehouse manager are your foot soldiers — They are on the ground, taking heavy fire, constantly working the battlefield. Whenever you’re visualizing a reform it is important to get their input. Why? They might surprise you with key information and advice you didn’t consider.

Not considering freight

The difference between pallet racking system quotes, sometimes, comes down to a few dollars. Sometimes between pallets A and B, the difference can be miniscule. A common mistake is not factoring in freight costs into the price. Sometimes the cheaper option might end up costing you an arm and a leg in transportation.

Used is just as good as new

Another mistake is believing that a used pallet racking system, one you can buy off auction websites or on the net, is just as good as a new one. If you’re looking for durability, usability, and strength it is better to buy something with that new car smell than a pallet system that has incurred damage throughout its lifetime. SRSI will coordinate setting up used pallet rack for customers if, and only if, the situation is a good fit for both parties.

Biggest Tip Of All

Our biggest tip is — Seek out professional advice. The biggest mistake people make is not contacting a professional when it comes to designing or buying a pallet racking system. Why? Because they want to save up on the consultation. This may end up costing you more in the long run. A professional can optimize your warehouse, give you tips on how to better pack in the pallets, and give you solutions to problems you hadn’t even taken into account. Specialists like the ones we have at SRSI can help you during the process — errors will end up wasting your space, costing you a lot in reforms, and quite possibly damage your operation. Don’t hesitate to give us a call.

Skip to main content

Skip to main content